Warning: Deprecated articles

You are using the old version of the knowledge base for ERPConnect.

Make sure to use the samples within the new HelpCenter for ERPConnect.

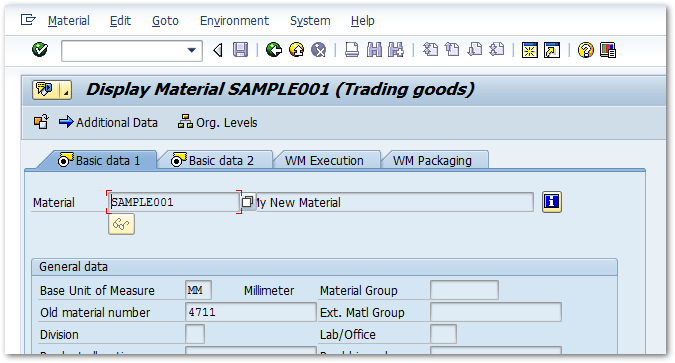

This sample shows how to create and read material master data in SAP using the BAPI BAPI_MATERIAL_SAVEDATA.

About #

A material object consists of multiple layers or so called views. Each view may exist multiple times, e.g., one plant view for plant 1000 and one for plant 2000 - both for the same material. To keep it simple, the provided sample code only shows how to handle the basic views. The other views work the same way.

The attributes of the basic view include:

- the Material Number

- the Old Material Number (which can come from a legacy system)

- the Industry Sector

- the Material Type (in this case HAWA - Trading Goods)

- the basic measure unit (mandatory).

Write Material Master Data #

The BAPI BAPI_MATERIAL_SAVEDATA can be used for both creating a new material or changing / extending an existing Material. Aside from the regular structure for submitting data (CLIENTDATA) there is an additional checkbox structure called CLIENTDATAX. Any data that is submitted in CLIENTDATA must be confirmed by an X value in the CLIENTDATAX structure.

The following sample code adds material attributes:

using System;

using ERPConnect;

// Set your ERPConnect license

LIC.SetLic("xxxx");

using var connection = new R3Connection(

host: "server.acme.org",

systemNumber: 00,

userName: "user",

password: "passwd",

language: "EN",

client: "001")

{

Protocol = ClientProtocol.NWRFC,

};

connection.Open();

RFCFunction func = connection.CreateFunction("BAPI_MATERIAL_SAVEDATA");

RFCStructure header = func.Exports["HEADDATA"].ToStructure();

RFCStructure basedata = func.Exports["CLIENTDATA"].ToStructure();

RFCStructure basedatax = func.Exports["CLIENTDATAX"].ToStructure();

header["MATERIAL"] = "SAMPLE001";

header["IND_SECTOR"] = "M"; // M stands for Mechanical Engineering

header["MATL_TYPE"] = "HAWA"; // Type HAWA stands for Trading Goods

header["BASIC_VIEW"] = "X"; // Just an X to indicate, that we want to create the basic view

basedata["OLD_MAT_NO"] = "4711"; // Old material number

basedata["BASE_UOM"] = "MM"; // Base Unit MM for milimeter

basedatax["OLD_MAT_NO"] = "X"; // X indicates, that we want to set this value

basedatax["BASE_UOM"] = "X"; // X indicates, that we want to set this value

// Add a row to the description text tables

RFCStructure descriptionrow = func.Tables["MATERIALDESCRIPTION"].AddRow();

descriptionrow["LANGU"] = "EN"; // Language of the text

descriptionrow["MATL_DESC"] = "My New Material"; // Actual Text

func.Execute();

// process return message

Console.WriteLine(func.Imports["RETURN"].ToStructure()["MESSAGE"].ToString());

// And Commit everything

RFCFunction funccommit = connection.CreateFunction("BAPI_TRANSACTION_COMMIT");

funccommit.Execute();

Console.WriteLine("\r\nPress Enter to exit");

Console.ReadLine();

Output:

The material SAMPLE001 has been created or extended

Read Material Master Data #

The following sample code reads the material attributes used in Write Material Master Data:

using System;

using ERPConnect;

// Set your ERPConnect license

LIC.SetLic("xxxx");

using var connection = new R3Connection(

host: "server.acme.org",

systemNumber: 00,

userName: "user",

password: "passwd",

language: "EN",

client: "001")

{

Protocol = ClientProtocol.NWRFC,

};

connection.Open();

RFCFunction func = connection.CreateFunction("BAPI_MATERIAL_GET_DETAIL");

func.Exports["MATERIAL"].ParamValue = "SAMPLE001";

func.Execute();

// Read data

RFCStructure basedata = func.Imports["MATERIAL_GENERAL_DATA"].ToStructure();

Console.WriteLine("Description Text: " + basedata["MATL_DESC"].ToString());

Console.WriteLine("Old Material No: " + basedata["OLD_MAT_NO"].ToString());

Console.WriteLine("Industry Sector: " + basedata["IND_SECTOR"].ToString());

Console.WriteLine("Material Type: " + basedata["MATL_TYPE"].ToString());

Console.WriteLine("\r\nPress Enter to exit");

Console.ReadLine();

Output:

Description Text: My New Material

Old Material No: 4711

Industry Sector: M

Material Type: HAWA